| Mount | Beveling | Cutting | Counterboring | Severing | Coating Removal | Facing | Weld joint removal | Surfacing |

| OD |

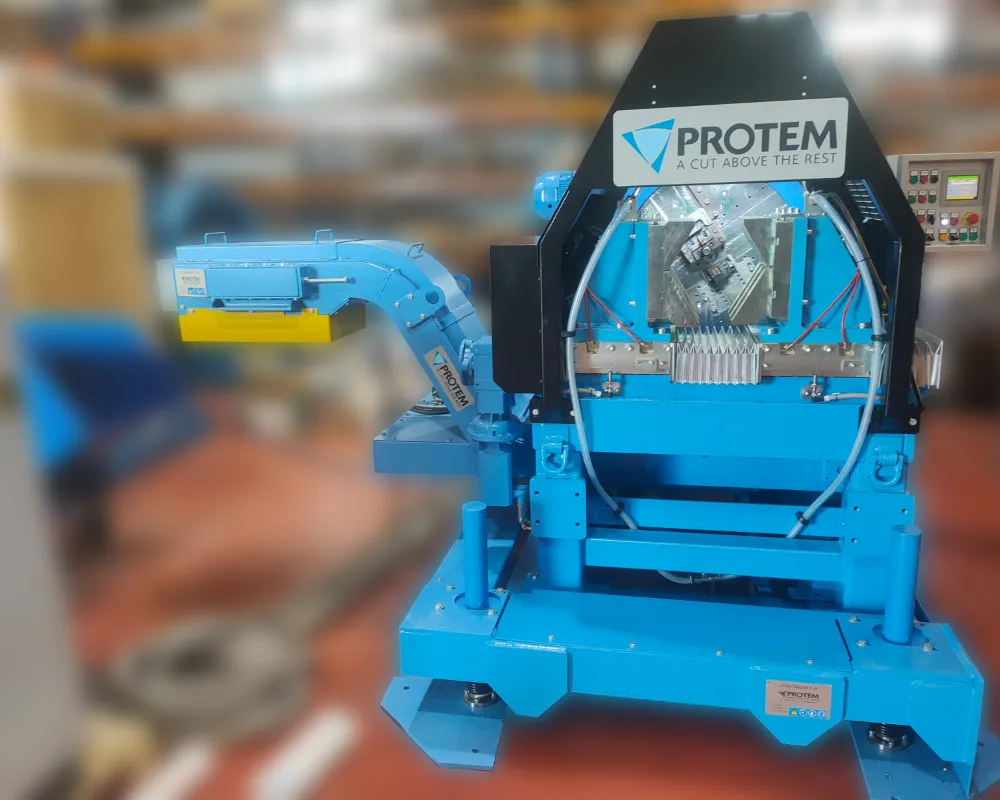

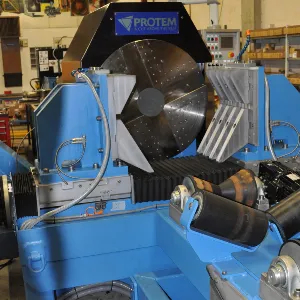

BB3-16 High Speed Beveling Machine

- for high-speed machining of heavy walled pipes

- designed single or simultaneous beveling, facing, and counter-boring heavy walled pipes

- for use on-site or in fabrication hops

- if required mounted on shop floor

- can easily switch to a new diameter via fast OD clamping system

- can be operated by single operator

- when used with optional tracking device, will machine oval pipes, leaving

a root face of a consistent width for excellent results in orbital welding

processes

| BB-3-16-V1-1000 | beveling bench for Ø 3"-16" (76.2mm - 406.4mm), maximum wall thickness 0.748" (19mm), electrical drive, manual clamping and feed |

| B-3-16-V3-1004 | beveling bench for Ø 3"-16" (76.2mm - 406.4mm), maximum wall thickness 1" (25.4mm), electrical drive, automatic clamping and feed |

| BB-3-16-V4-1006 | beveling bench for Ø 3"-16" (76.2mm - 406.4mm), maximum wall thickness 1.417" (36mm), electrical drive, automatic clamping and feed |

Technical Features

| machining capacity | standard: min. dia. 76.2 mm (3") max. dia. 406.4 mm (16") |

| mounting | OD mount min. dia. 76.2 mm (3") max. dia. 406.4 mm (16") |

| specific shapes & angles | I, V, X, J-bevel, other on request |

| clamping | manual, semi-automatic, automatic |

| feed | manual & automatic |

| feed stroke | 3.937" (100mm) |

| machining time | a few seconds |

| motor power | 30 kW |

| machining | carbide insert |

| electric drive | 110V, 220V and 380V |

Information provided is not contractual and subject to change without prior notice.