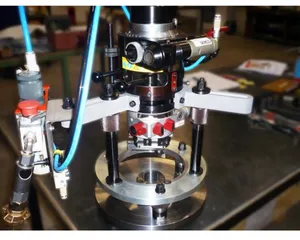

TU Series:

TU400 Portable Facing and Boring Equipment for Flanges and Valves

- are designed for use under extremely difficult and restrictive conditions

- have separate and independent parallelism and concentricity adjustment mechanisms

- through two-stage setup eliminates the need for re-adjustment of parallelism after concentricity has been adjusted

- provides up to 0.01mm precision and up to 1.6 Ra surface finish

- offer a combination of reduced size, weight, economic design, ultra-high precision surface machining and / or boring results

TU400

- is perfectly suitable for machining operations need to be done in confined space

- offer both automatic and manual axial and radial movement feed mechanisms without compromising 0.01mm machining precision

- when used with RTJ system performs conical machining function

Information provided is not contractual and subject to change without prior notice.