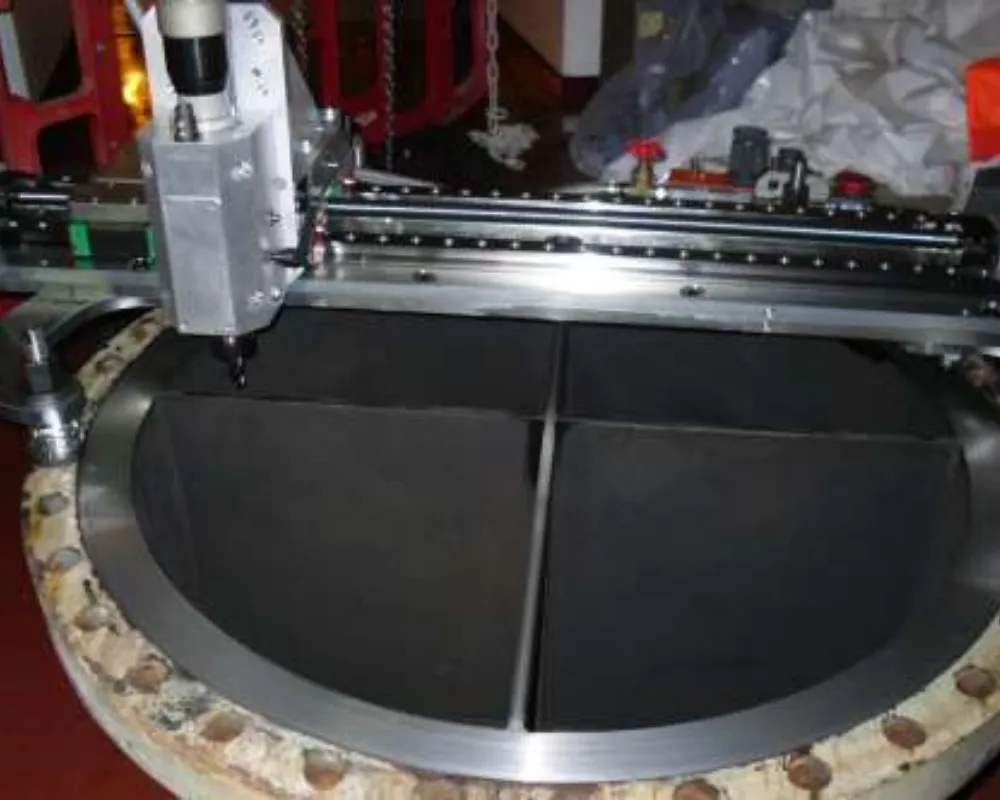

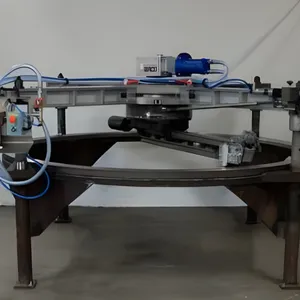

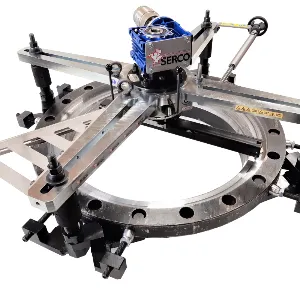

XP Series

BDF1100 Milling Unit

- is designed for carrying out numerous milling operations (surfacing, slotmilling, beveling, drilling, tapping, cutting with milling saw, etc. on flanges or sheeting on site or in the workshop

- can be used horizontally or on as vertical axis

- it clamping and adjustable foot system provides a machining range up to 40.35” (1025mm)

| BDF1100-1000 | grooving and bench for Ø 0" - 40.354" (0mm - 1025mm |

| BDF2100-1000 | grooving and bench for Ø 0" - 82.677" (0mm - 2100mm) |

Technical Features

| Pneumatically driven longitudinal and spindle feeds | pressure 6 bar / flow 2600 liter /min |

| Cross-feed and down-feed | manual |

| power-driven longitudinal feed | P = 120W |

| movement | 1025mm' reversible and declutchable by preloaded ball-screw and nu |

| manual rapid longitudinal feed | gearbox with handle and multiplier gear (ratio: 3) |

| longitudinal guiding | pre-loaded roller bearings mounted on rails |

| cross-traverse carriage | movement 1.968" (50mm), dovetail guiding, precision vernier scale and lock screw |

| cutter down-feed | movement 3.934" (100mm) with vernier scale and locking handle |

| milling spindl | mounted on a support bracket (3 possible positions) power 1500 W. Movement 3.934" (100mm), with SA taper adapter, cutting spindle with ER collet (up to diameter 0.787" (20mm)) |

| FRL pnuematic unit | with emergency stop and drive control |

| weight and dimensions | 425 lbs (193kg) 59.44" x 25.56" x 19.29" (1510 x 700 x 490 mm) |

| options | |

| include right-angle attachment on the spindle for sawing and saw-milling power-driven radial movement is possible milling units with different lenghts of movement can be designed |

Information provided is not contractual and subject to change without prior notice.