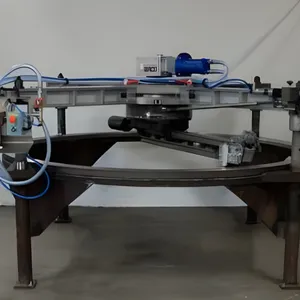

XP Series

XP1800NG Portable Facing and Boring Equipment for Flanges and Valves

- Have a very compact design for use in extremely confined spaces

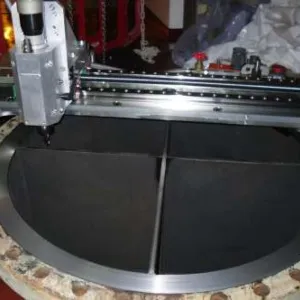

- Have a very large range of radial movement and are ideal for facing operations on valves and flanges

- Their inclinable head option allows machining RTJ grooves

- Have separate and independent parallelism and concentricity adjustment mechanisms

- Provide up to 0.01mm precision and up to 1.6 Ra surface finish

- Can be set up easily even in the tightest spaces, and in all positions, by one operator

- Clamp outside of the part to be machined via a clamp/arm system that fixes and keeps the machine strictly in the adjusted position

XP900NG:

- can be set up at site by two operators without any handling device

- via powerful motorization options can perform flange maintenance

operations in record times

Information provided is not contractual and subject to change without prior notice.