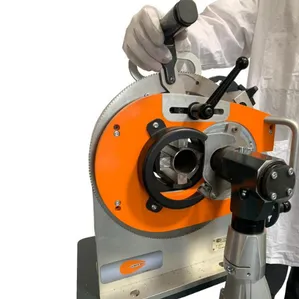

RTJ System for TU machines

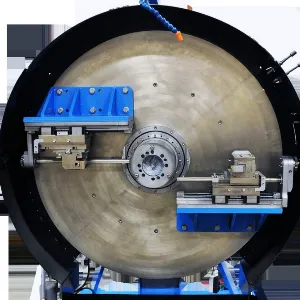

- does conical machining – machining 2 slopes, inside and outside at an angle of 23° to vertical

- groove machining.

- Conical machining for RTJ groove bearing surfaces is done using an automatic feed combining the radial and axial feeds on the SERCO portable machine

- Angular accuracy / Machining accuracy: 0.01mm / Surface finish: Ra 1.6

| TU400RTJ-1000 a | attachment for machining 23° slopes (ring type joint bearing surface) |

| TU600RTJ-1000 | attachment for machining 23° slopes (ring type joint bearing surface) |

| TU1000RTJ-1000 a | attachment for machining 23° slopes (ring type joint bearing surface) |

Technical Features

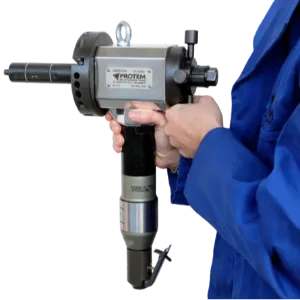

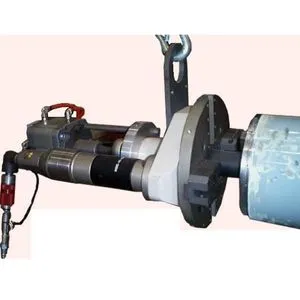

| SERCO RTJ machine is designed for | - horizontal machining - facing |

| - vertical machining - boring | |

| - conifal machining - RTJ (23°) or any angle (30°, 45°, etc.) | |

| RTJ technical principles: | |

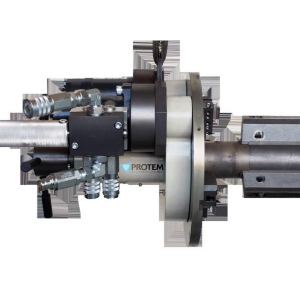

| angular gearbox | driven by the rapid return system on the boring head |

| universal joint | for transmitting the rotation movement in a vertical plane |

| gear / wheel assembly | drives the gear vai the universal joint. the machine is positioned on the machine vernier scale support |

| clutch system | for engaging the gear on the wheel for generating the down-feed movement at the angle defined beforehead |

| down-feed | as per pre-defined angle |

Information provided is not contractual and subject to change without prior notice.